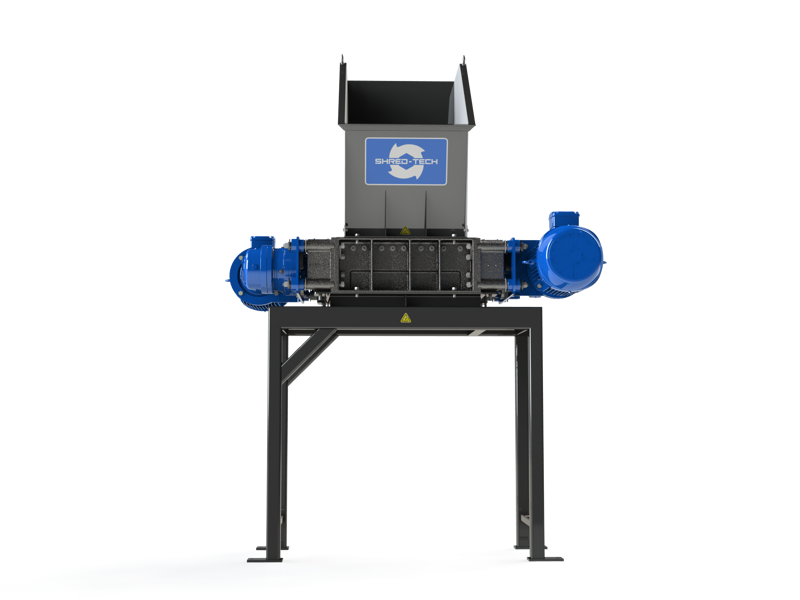

The ST-25 Industrial Shredder is outfitted with a series of sharp and durable knives that have been designed to bite straight through a range of products and materials. These powerful knives can eat through bulky loads with ease, tearing the materials into shreds as though they were made of butter. Each knife is 7 3/4” in diameter, giving them plenty of strength to shred paper, boxes, plastic parts, hard drives, and more.

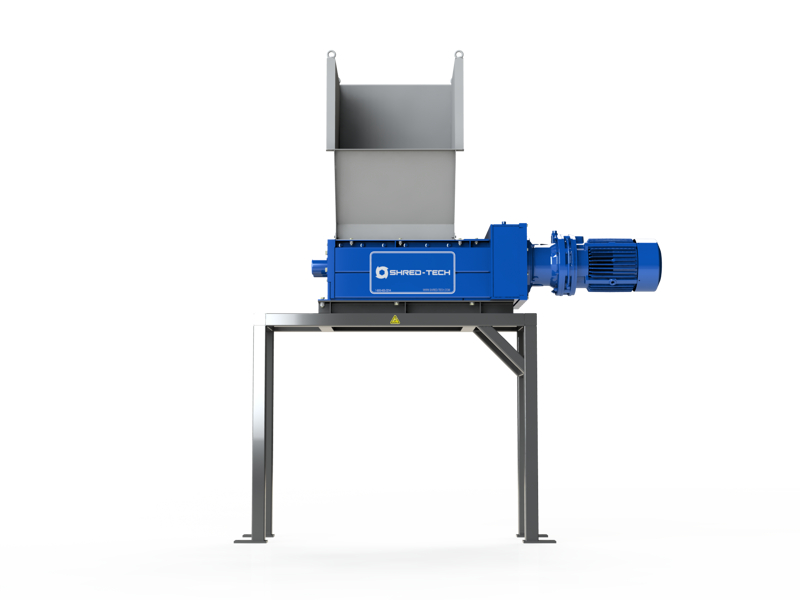

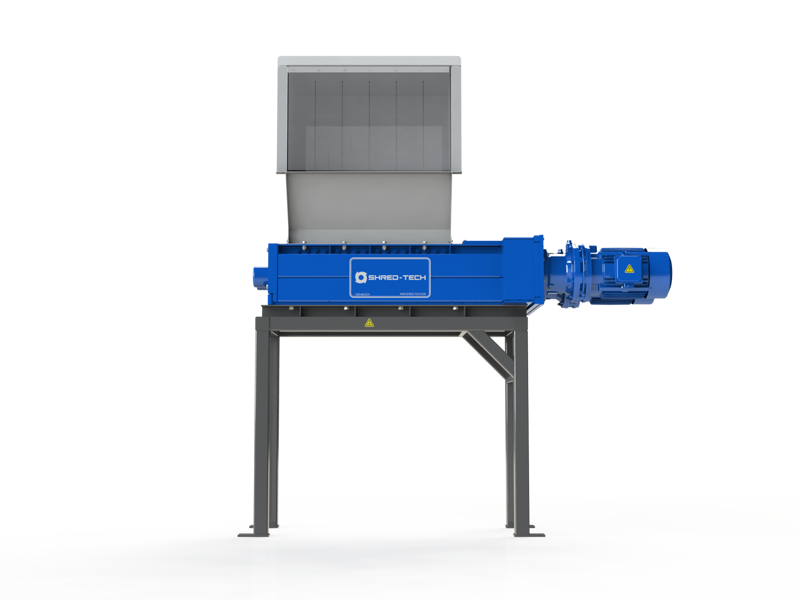

Shred-Tech ST25

Your company can easily experience optimized shredding efficiency once you install and utilize the high-quality power of the Shred-Tech® ST-25 Industrial Shredder. This compact machine is the ideal solution for businesses looking to maximize cost effectiveness and revenue as it provides you with equal amounts of power and durability. Offering a light-duty throughput of up to 1 ton per hour, the shredder is designed to allow you to keep the workflow moving without interruption so you can keep up with the growing demands of the industry. The superior performance of the ST-25 Industrial Shredder makes it the ideal model to drive your business forward and past the competition.

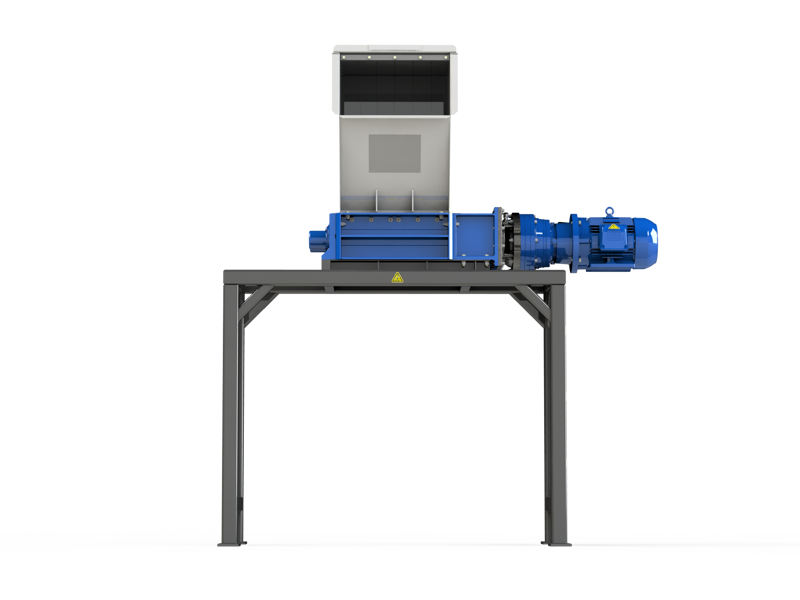

This high-quality shredder works excellently with material up to 16” x 27.5” in size and can effectively reduce bulky loads into easy-to-manage scraps for further processing and use. The machine can be used for a variety of applications, including moulded car parts, circuit boards, confidential documents, sharps, medical waste, hard drives, and much more. The shredder is available with a wide range of gear reduced drive ratios fitted with 15, 20, or 25 HP electric motors. Our highly skilled and experienced engineers have included several design refinements to increase the ease of maintenance and shredder durability for the ST-25 Industrial Shredder, including a new torque tube body design that works effortlessly with the increased shaft hex thickness, knife diameter, and spacer thickness.

Standard Features for the ST-25

The dedication of our engineers has resulted in a high-performance ST-25 Industrial Shredder that offers superior durability and higher service factors thanks to the excellent quality of its standard features. Along with bulkhead walls and labyrinth barriers at either end of the cutting chamber, the machine is equipped with other standard features that improve the quality of the shredding process. These include highly durable knives, sturdy hex shafts, and a user-friendly control panel. Each component is engineered to enhance the overall shredding experience for improved serviceability and uptime.

Optional Extras

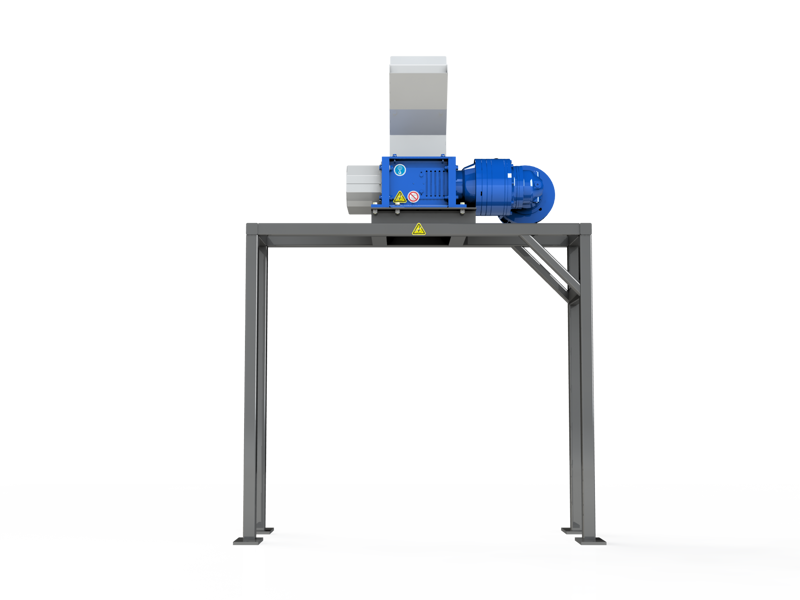

Along with our offering of high-quality standard accessories, our engineers have also created a variety of solid and reliable optional accessories for the ST-25 Industrial Shredder. Each of these components is engineered to provide optimal support that can push the shredder to its peak capabilities. Among our optional accessories, we offer a hopper, in-feed conveyor, out-feed conveyor, and stand, while further accessories can be added upon request. The Shred-Tech® team is available 24/7 to help you customize your ST-25 Industrial Shredder as well as answer any questions about how we can create a tailored shredding and recycling solution that drives your business forward for years to come.

Technical Specification

- Throughput: 1t/hr

- Size of Material (LxW): 16" x 27.5"

- Shred Size/Fraction Size: Strips (Inconsistent)

- Drive: Electric

- Number of Motors: 1

- Knife Thickness: 3/8", 5/8", 7/8", 1 3/16"

- Number of Knives: 72, 40, 32, 24

- Knife Diameter: 7 3/4"

- Hex Size: 2 11/16"

- Distance Between Shafts: 5 7/8"

- Cutting Chamber (LxW): 27 1/2" x 16"

- Discharge Height: 40"

- Hopper Height: 20"

- Application: Plastic

- Application: Metal

- Application: Paper

- Application: E-Waste

- Application: Medical Waste

- Application: Textile & Carpet

- Application: Aluminium

- Application: General Waste

- Application: Circuit Boards

- Shredder Horsepower: 15-25 HP