The superior cutting force of the ST-300 Industrial Shredder comes from out high-quality manufactured knives. Our engineers have engineered each knife profile and configuration for optimal usage and strength. They can easily bite down right into the thicker material, such as steel drums or wooden pallets, and eat their way through them as if they were made out of soft butter. The knives are designed to suit the application for optimal throughput and maximum shred size, cutting the products down into easy-to-manage scraps.

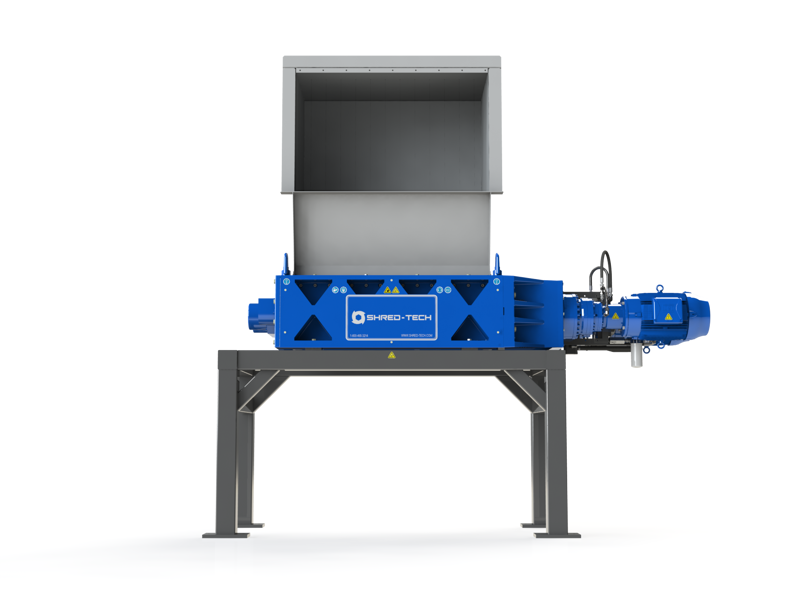

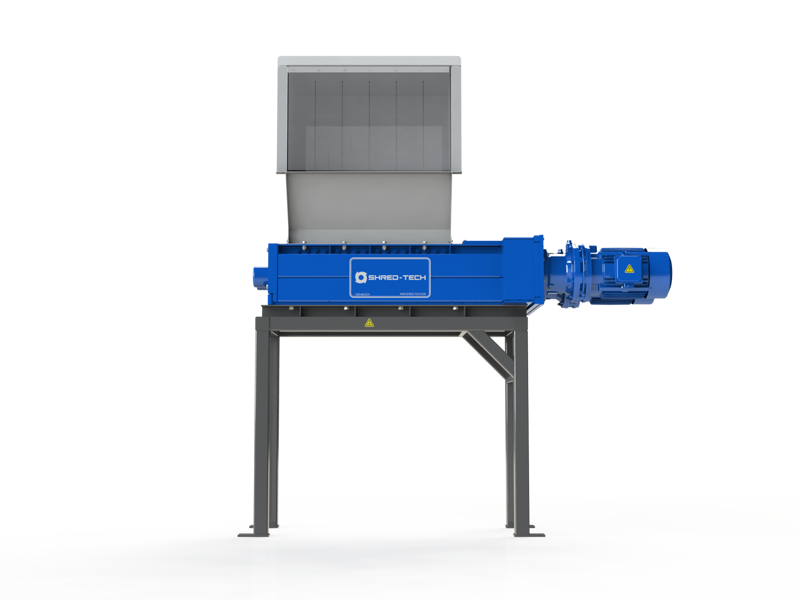

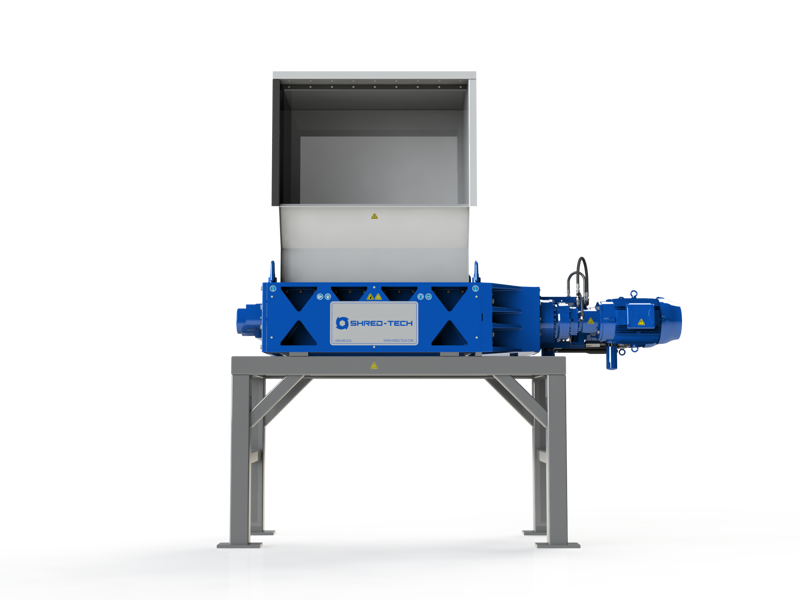

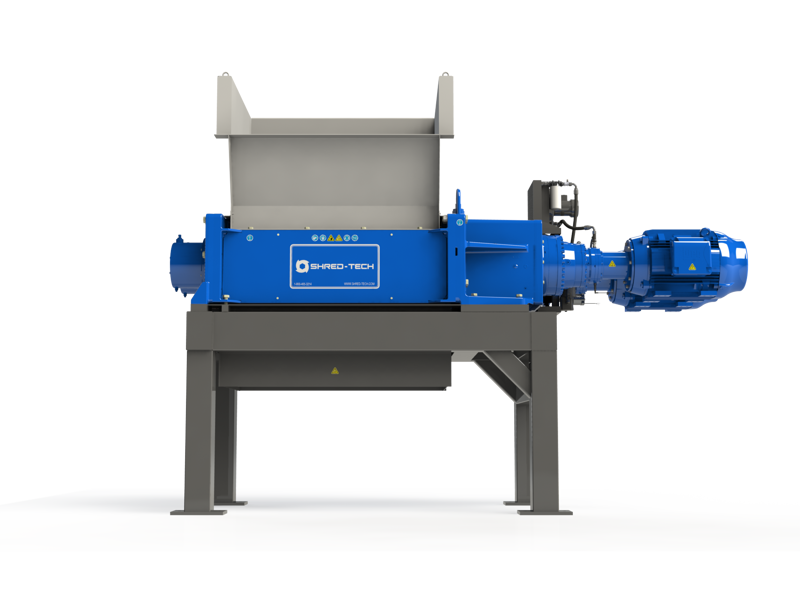

Shred-Tech ST-300

Once your company acquires the high-quality Shred-Tech® ST-300 Industrial Shredder, you will be able to experience an improvement in efficiency. This heavy-duty shredder machine is engineered for optimal performance and versatility, making it the ideal choice for any shredding company. It provides you with the power to effectively tear through some of the tougher materials, such as steel drums, auto and truck tires, municipal and industrial waste, mattresses, wood, and more. Offering a heavy-duty throughput of up to 3 tons per hour, this shredder can increase your workload to keep up with the constant demands of the shredding industry. It is an excellent model that is designed for maximum use for a variety of applications and for optimum shred size.

The ST-300 Industrial Shredder is engineered by our experts for optimized efficiency. It features a large cutting chamber and works excellently on 40” x 65” sized material so that it can easily handle the bulkier loads without interrupting the workflow. It comes available with dual 50, 75, 100, or 150 HP electric motors. The shredder machine also features several design refinements that increase the ease of maintenance and shredder durability. Its new cast steel body design can withstand the tougher loads while the bulkhead walls and labyrinth barriers at the end of the cutting chamber protect the bearing and seal. This combination of expert manufacturing has resulted in superior durability and higher service factors for the industrial shredder.

Standard Features for the ST-300

For optimal usage, the ST-300 Industrial Shredder is equipped with a number of standard features that help improve the overall performance of the machine. These components are each designed to provide maximum support to guarantee greater serviceability and versatility. These configurations, which include the biting knives, durable hex shafts, and user-friendly control panel, are manufactured to not only meet but surpass your expectations. In addition, the industrial shredder has sectional cleaning fingers, which are removable from the top, and a lightweight chamber plate that ensure quick and easy cutting chamber disassembly for faster and simpler maintenance.

Optional extras

If you would like to experience the ST-300 Industrial Shredder at maximum use, we offer a variety of optional accessories that work well with the shredder machine. These components are each designed to provide optimized support to keep the shredder working at top capacity. The options include a durable hopper, convenient in-feed and out-feed conveyors, and a supportive stand. To learn more about how Shred-Tech® can provide you with other optional accessories that can help you create the ideal industrial shredder for your company, you can easily contact the Shred-Tech® sales team.

Technical Specification

- Throughput: >3t/hr

- Size of Material (LxW): 40" x 65"

- Shred Size/Fraction Size: Strips (Inconsistent)

- Drive: Electric

- Number of Motors: 2

- Knife Thickness: 1 5/8", 1 7/8", 2 1/3", 2 7/8"

- Number of Knives: 43, 34, 27, 22

- Knife Diameter: 20"

- Hex Size: 6 5/8"

- Distance Between Shafts: 15"

- Cutting Chamber (LxW): 65" x 40"

- Discharge Height: 48"

- Hopper Height: 50"

- Application: Wood

- Application: Plastic

- Application: Metal

- Application: Paper

- Application: E-Waste

- Application: Medical Waste

- Application: Tires & Rubber

- Application: MSW

- Application: Textile & Carpet

- Application: Pallets

- Application: Aluminium

- Application: General Waste

- Application: Computers

- Application: Batteries

- Application: Alkaline Batteries

- Application: Nickel Batteries

- Application: Lead Batteries

- Application: EV Batteries

- Application: Lithium Ion Batteries

- Shredder Horsepower: 100-300 HP