For optimal cutting capabilities, the ST-75 Industrial Shredder is equipped with several highly destructive knives. Each knife profile and configuration has been carefully designed by our engineers to meet the application for optimized throughput and maximum shred size. Offering superior cutting strength, the knives work flawlessly together to slice right through thick material until only scraps remain. Their sharp and durable frames and biting tips can eat through products with both ease and efficiency.

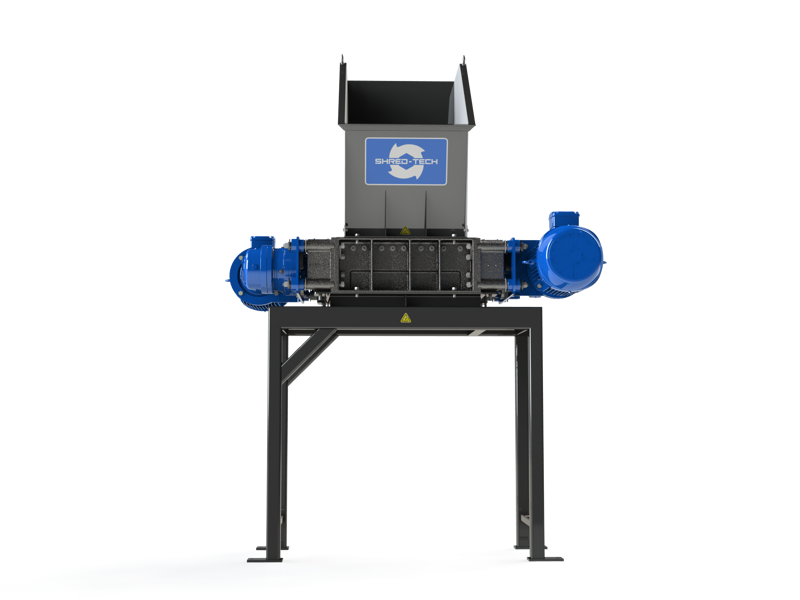

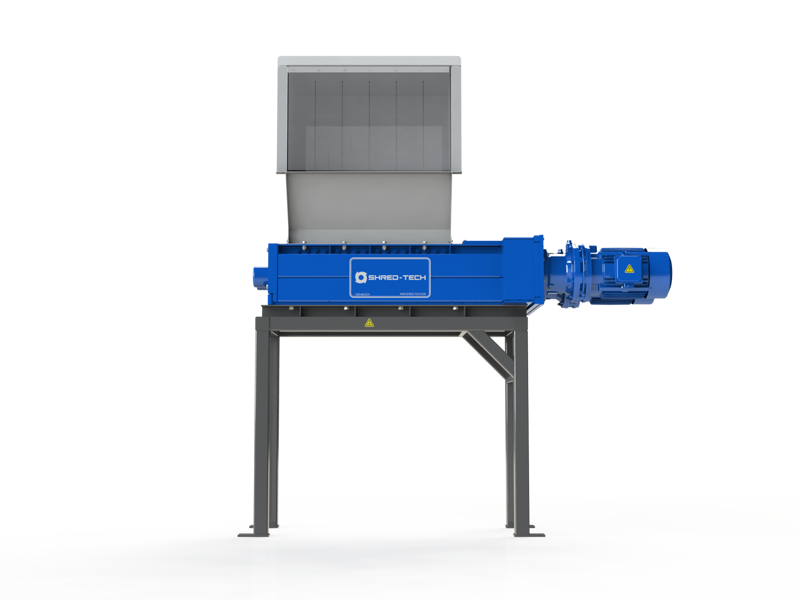

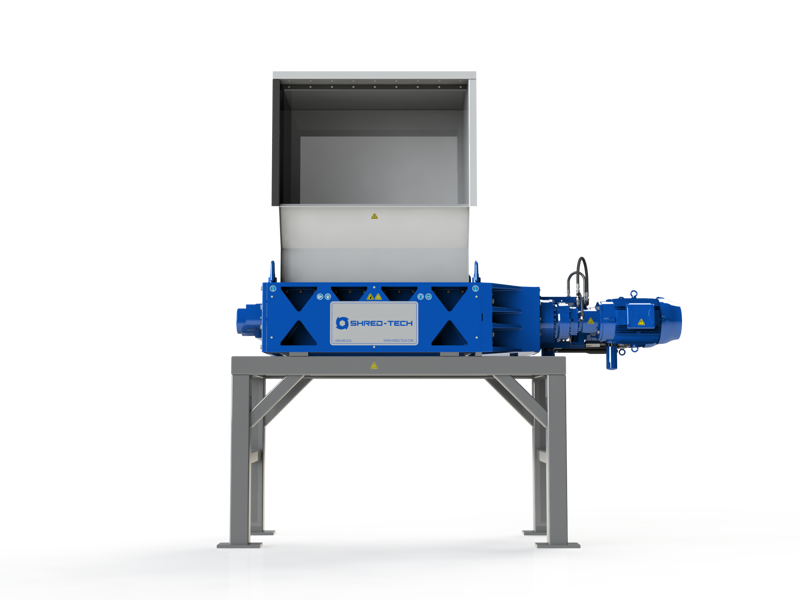

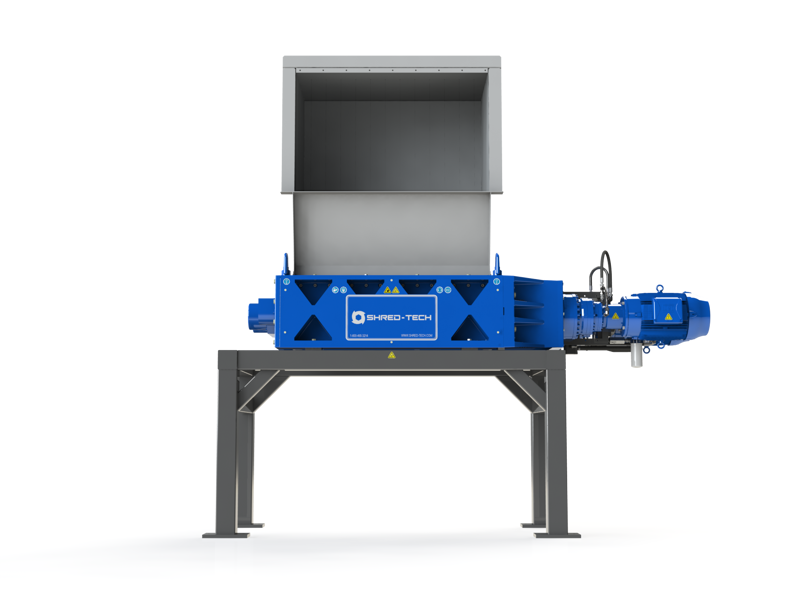

Shred-Tech ST-75

Shred-Tech® can meet your requirements and surpass your expectations with our high-performing ST-75 Industrial Shredder. This heavy-duty shredder machine has the much-needed strength to rip through bulky and tough materials as if they were made of butter. It is a powerful but cost-effective machine that can help you and your business outperform your competitors in this growing industry. It combines high performance with great versatility, culminating in a superior industrial shredder that is perfect for established businesses looking to expand and scale their operations.

The ST-75 Industrial Shredder features a 25” x 50” cutting chamber size that is capable of tearing through many solid products, such as steel drums, plastic drums, fabrics, steel and aluminium stampings, high-volume confidential waste, and more. It offers a medium-duty throughput of between 1 to 3 tons per hour, allowing you to shred through your items at an increasingly efficient rate. The industrial shredder is designed to help decrease your business’s footprint while offering greater opportunities for your company to expand into new segments while broadening your customer base. The bulkhead walls and labyrinth barriers are positioned at each end of the cutting chamber for effective protection for the bearing and seal. Replacement for the bearing and seal can be easily done without the need for a gearbox disassembly so maintenance and repairs are always fast and simple.

Standard features for the ST-75

Our ST-75 Industrial Shredder is engineered by experts to outperform in this industry, and it comes with a variety of standard accessories that enhance its overall performance. Its cast aluminium body design combines with an increase in shaft hex thickness, knife diameter, and spacer thickness to create a high-quality machine that is superior in durability with higher service factors. It also features easily removable sectional cleaning fingers and a lightweight chamber plate for quicker and easier cutting chamber disassembly. Each of these components works effectively together to provide you with an industrial shredder that is high in serviceability for better ROI.

Optional extras

We offer many optional accessories for the ST-75 Industrial Shredder that work to not only improve the performance of the machine but also make the job easier for operators. Among others, we have the durable hopper, the convenient in-feed conveyor and out-feed conveyor, and the stabilizing stand. These options allow you to configure the shredder to fully meet your requirements. For even more optional accessories and information on how Shred-Tech® can work with you to create the ideal solution to suit your specific application or requirements, contact our expert team today, which is available 24/7!

Technical Specification

- Throughput: 1-3t/hr

- Size of Material (LxW): 25" x 50"

- Shred Size/Fraction Size: Strips (Inconsistent)

- Drive: Electric

- Number of Motors: 1 or 2

- Knife Thickness: 5/8", 7/8", 1", 1 1/2", 2"

- Number of Knives: 72, 64, 48, 32, 24

- Knife Diameter: 12 1/2"

- Hex Size: 4 5/16"

- Distance Between Shafts: 9 7/16"

- Cutting Chamber (LxW): 50 1/8" x 25"

- Discharge Height: 42"

- Hopper Height: 34"

- Application: Wood

- Application: Plastic

- Application: Metal

- Application: Paper

- Application: E-Waste

- Application: Medical Waste

- Application: Textile & Carpet

- Application: Aluminium

- Application: General Waste

- Application: Computers

- Application: Batteries

- Application: Alkaline Batteries

- Application: Nickel Batteries

- Application: Lead Batteries

- Application: EV Batteries

- Application: Lithium Ion Batteries

- Shredder Horsepower: 60-100 HP