For maximum heavy-duty durability, the STQ-50 Industrial Shredder features high-quality construction based on Shred-Tech®’s standard torsion tube body concept, which ensures reliable robustness and trouble-free operation. Built by our highly skilled engineers, the body of our shredder machine can endure daily use while keeping up with the demands of the industry. Our proprietary triple seal cutting chamber is equipped with abrasion resistant wear components along with exceptionally high knife tip cutting force. These features combine to effectively ensure a number of advantages, including low noise and vibration, reduced wear, and decreased maintenance costs.

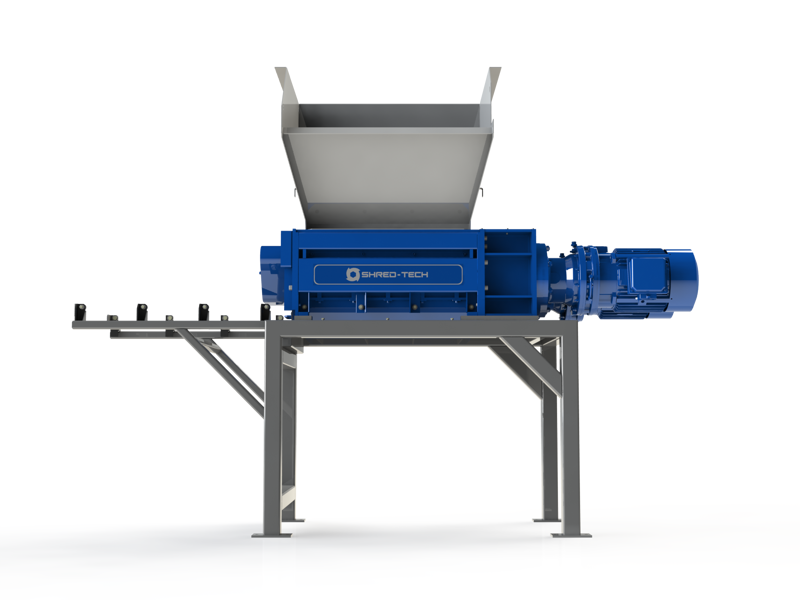

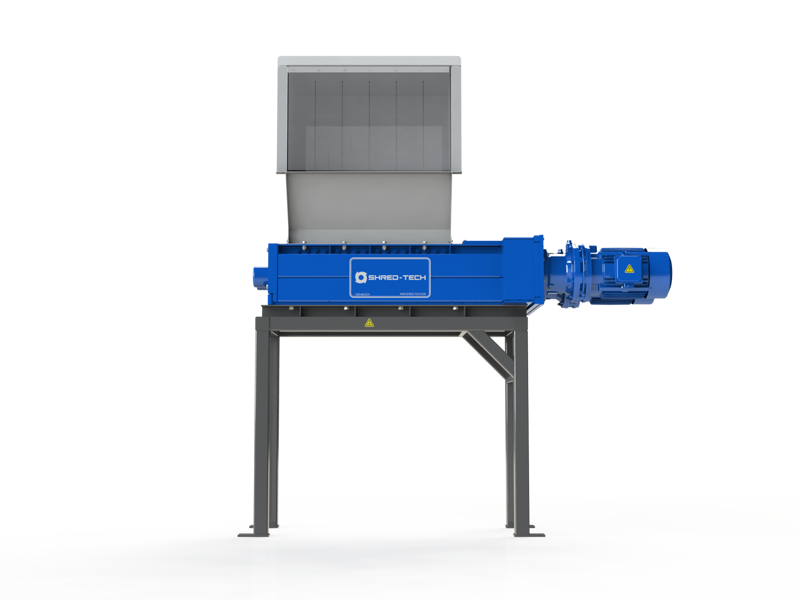

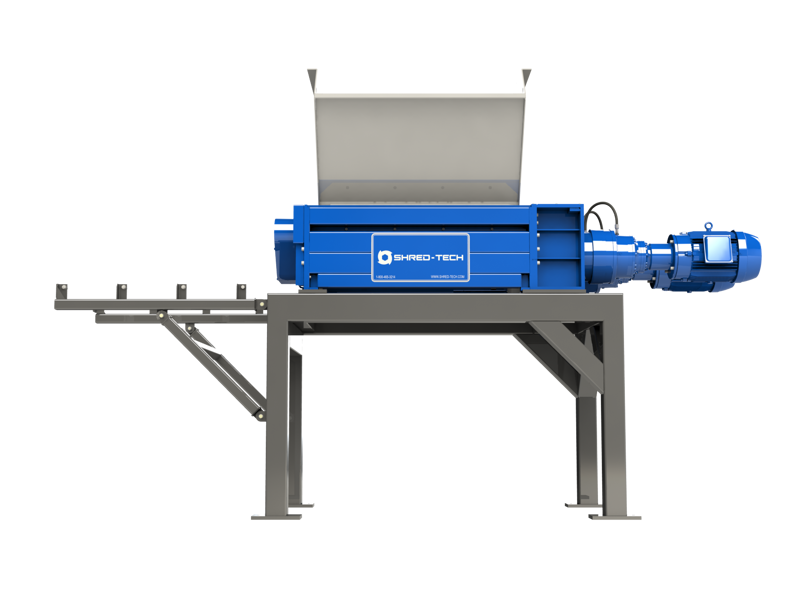

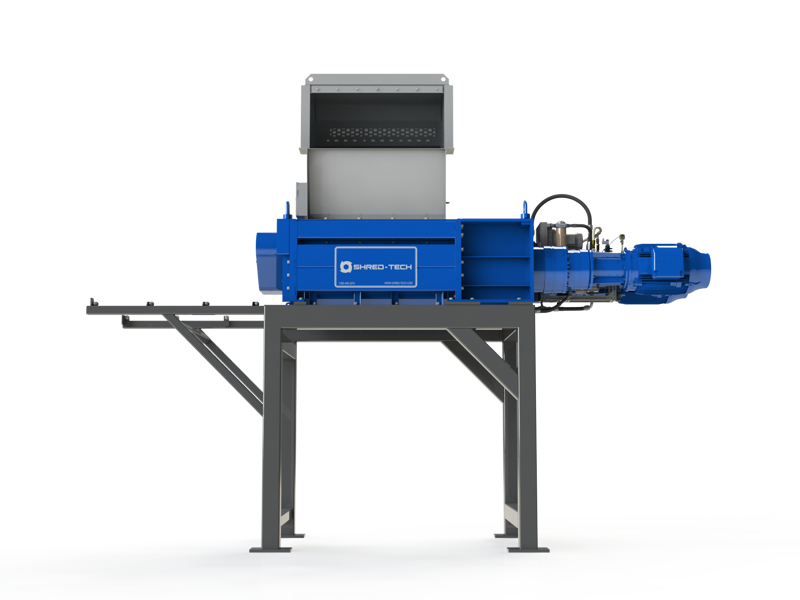

Shred-Tech STQ-50

Powerful shredding is right within your grasp once you acquire the high-performing Shred-Tech® STQ-50 Industrial Shredder for your business. This powerful machine is more than capable of handling the intense workflow of the industry and keeping up with constant demands so you can easily outperform your competitors. It is designed by our expert engineers to process bulk materials, which include plastics, wood, textiles, organic waste, medical waste, electronic equipment, and more. The blades within the shredder bite through and rip apart the products, rendering them into a uniform particle size in a single pass. It works in an efficient and timely manner, getting more done so that you can do more.

The STQ-50 Industrial Shredder operates with a medium-duty throughput of up to 1-3 tons per hour, offering you efficient and effective shredding throughout its service. It works with 28” x 49” sized materials to reduce them into consistently sized pieces of scrap for further processing and use. Built for durability as well as ease of operation, the industrial shredder features simplified modular construction that reduces the number of major components while increasing parts commonality, thus helping to reduce spare parts requirements. The bulkhead walls and labyrinth barriers are located on each end of the cutting chamber for bearing and seal protection. Replacement for the bearing and seal is easily done without the need of gearbox disassembly. The STQ-50 Industrial Shredder comes with a 1-year or 2,000-hour warranty to protect your investment, and our engineers are easy to contact should you need assistance with maintenance, service, or spare parts.

Standard Features for the STQ-50

The STQ-50 Industrial Shredder is designed to process bulk materials and products and reduces them to a uniform particle size in a single pass, and a variety of standard features help enhance the shredder’s performance. These components work together to ensure that your business experiences powerful and efficient shredding to suit your applications and exceed your expectations. This high-performing shredder machine features robust construction, highly sharp cutting knives, durable hex shafts, and a convenient rollout screen. The machine outperforms in the shredding industry as it easily handles day-to-day applications with improved efficiency.

Optional Extras

A wide range of optional accessories are also available for the STQ-50 Industrial Shredder in order to fully customize this versatile machine to suit your ideal specifications. Each component is designed to enhance the overall performance of the shredder machine so that it provides you with optimized serviceability. We offer a range of accessories to improve support and convenience for the entire shredding system, including tough hoppers, durable stands, and highly efficient and easy-to-use in-feed and out-feed conveyors, among others.